A bright mind always desires and pursues ideas that can change the world. When knowledge, creativity, inspiration and innovation collide, novel concepts are quickly generated and a “eureka” moment ensues. For Sherwin Seligsohn, founder of Universal Display Corporation (UDC), it was a real “light”—a tiny green dot—that inspired him to embark on the path of innovation in display materials. It also changes the way we perceive the world.

In 1994, Sherwin Seligsohn visited the electrical engineering school at Princeton University and he observed research by Drs. Forrest and Thompson in self-emissive organic materials. He saw a green dot, with a 9-volt battery hanging from it, light up for seconds before it expired. From that green dot, Sherwin saw the future of display technology, and so began Universal Display’s story.

Fast forward almost two decades and UDC has grown from an R&D start-up to a global leader in the OLED industry. Today, about half of the world’s smartphones use energy-efficient phosphorescent OLED materials in the display panel. UDC’s proprietary technologies and materials can be found in virtually every commercial OLED product in the world, such as smart watches, laptops, tablets, TVs, AR/VR devices, and automobiles.

From the discovery of the “green dot” to the advent of modern OLED display devices, the display industry has gone through many technological iterations and changes before realizing the widespread use of OLED technology in various types of electronic products that are popular around the world. Compared with the brief moment of “eureka”, the process of innovation is often complex and slow. It requires a systematic research and development process to achieve breakthroughs, meet customer needs, and open up new paths forward.

Before OLED technology entered the market, cathode ray tube TVs were a display technology more familiar to consumers. Although LCD TVs had greatly improved and received a lot of attention at the time, the display industry was still full of the possibility of disruptive technologies.

In 1996, Universal Display became a publicly traded company with a research contract with Princeton University, 3 part-time employees and one patent pending.

However, the entry barrier to the display industry is relatively high, and although backplane technology has become increasingly mature, an ecosystem that can support the popularization of OLED displays throughout the consumer electronics field has not yet been formed globally.

In addition, various technological research and development in the display industry still need to overcome various complex scientific and engineering challenges, such as developing commercial phosphorescent OLED (PHOLED) materials that meet the color and service life required for high-performance consumer electronics. At the same time, consumers keep and use devices for years, far longer than the first few seconds when that green dot appears. Therefore, in addition to inventing and promoting phosphorescent OLED materials that meet consumer needs, innovative luminescent materials must also be able to be produced in large quantities, and the purity requirements of luminescent materials may even be higher than the specifications of some pharmaceuticals.

Even after overcoming initial R&D challenges, UDC faces new challenges in implementing phosphorescent OLED materials into devices in the field. Before the emergence of UDC technology, many display manufacturers were not only suspicious of OLED materials when they first came into contact with them, but also tended to associate OLED technology with inefficient fluorescent technology. In addition, OLED fluorescent materials also face the problem of high energy consumption and are not competitive at all compared with LCD technology. When UDC launched phosphorescent OLED materials that can reduce energy consumption to 1/4 to 1/3 of the original, there was a huge reversal in the attitude of major manufacturers, and OLED technology also received great attention from the market as a whole.

Thanks to its wide application potential, phosphorescent OLED technology has gradually gained favor from OLED display panel manufacturers. At this time, another big challenge came: engineers needed to update the design of the TFT backplane used to drive the display. Fortunately, backplane changes are a routine part of the design cycle, so panel manufacturers can quickly introduce energy-efficient OLED technology into production and quickly realize the technical advantages of phosphorescent OLED.

Another reason why OLED technology is favored by the market is that it can achieve breakthrough in the form factors and stunning visual effects. Liquid crystal displays (LCDs) are usually limited by the hardness of the glass panel, while OLED technology uses a multi-layer organic thin film structure to produce electroluminescence and can be deposited on glass, plastic or even metal foil. At the same time, OLED itself can be flexible, bendable and rollable. While these attributes were not immediately available in the early days of OLED technology, they play a part in building the ubiquitous OLED future envisioned by Seligsohn and UDC.

Finally, OLED has the advantages of a wide color spectrum, fast response time, nearly infinite contrast ratio in dark conditions, thin and light shape, and 180-degree viewing angle, and can present excellent visual performance. In addition, because phosphorescent OLEDs also have high energy efficiency, manufacturers have become keen on using OLED technology in various consumer electronics products.

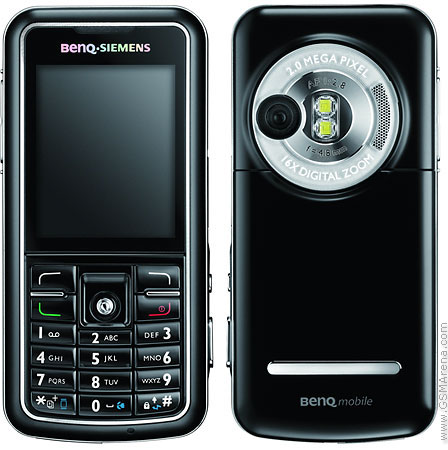

In the early stages of the development of the OLED market, the application of this technology in consumer electronics was mainly concentrated in products such as mobile phones and MP3 players. Since battery life is an important consideration for mobile products (and still is today), improvements in OLED technology and materials have allowed OEMs to offer displays that are more efficient than mainstream LCD display technology. The first commercial display using phosphorescent OLED technology was used in a flip phone released by Fujitsu in 2003. The phone uses red phosphorescent OLED material as part of a small sub-display on the front of the enclosed flip phone, which allows users to read the time and date. Just three years later, phosphorescent OLED materials were used in the first commercial active-matrix OLED display phone, the BenQ-Siemens S88.

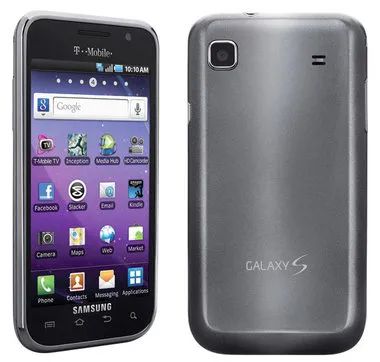

The real rise of OLED came after smartphones entered the market. Smartphones offer high-quality displays and performance, prompting consumers to transform their phones from communication tools primarily used for calling and texting to mobile internet terminals.

In 2010, Samsung Electronics launched the Galaxy S, its flagship smartphone equipped with an OLED display, which triggered a wave of strong attention in the industry. Samsung’s continued efforts in producing high-quality, energy-efficient OLED displays have also promoted the development of the OLED industry, promoting huge investment in production capacity and the continued popularity of OLED.

Since then, the OLED industry has boomed. Today, about half of the smartphones on the market use OLED screens. OLED TVs, meanwhile, are consistently rated as the best TVs in the world. From the initial launch of OLED to today, strong customer partnerships and reliable supply of high-performance, energy-efficient materials have proven to be the key to promoting the development of the OLED industry, and they are the important driving forces which propel the improvement and popularity of OLED technology in the coming years.

As the OLED market continues to grow, UDC has further expanded its investment in China and is committed to better providing local customers with various services and on-site support. Specifically, UDC has currently set up offices in Beijing, Shanghai, Chengdu, Shenzhen, Hong Kong, and Taiwan to strengthen and expand local support for China’s OLED industry. UDC’s laboratory in the Hong Kong Science and Technology Park includes the most advanced phosphorescent OLED application center. The application center not only helps and enhances UDC’s local business and services, but also provides local customers with on-site device preparation and testing.

As various companies pay increasing attention to energy efficiency issues, outstanding scientists and engineers engaged in OLED technology research are constantly breaking through various barriers. Currently, the commercial phosphorescent OLED product portfolio mainly includes red and green phosphorescent materials (both of which have been widely used in mobile phones, tablets and laptops), and yellow-green phosphorescent materials (used in some OLED TVs). In terms of energy consumption, compared to LCD devices, devices using phosphorescent OLED materials are more energy-saving. UDC is the exclusive supplier of phosphorescent OLED materials to several major display panel manufacturers. The company’s blue phosphorescent material plans to officially enter the commercial market in 2024, and is expected to further improve the energy efficiency of OLED displays by about 25%, while also enhancing the performance of products in the entire consumer electronics market.

UDC’s team is also working on research and development of plasmonic phosphorescent materials (Plasmonic PHOLED). The technology is an exciting new OLED device architecture that extends the life of OLED panels and further improves energy efficiency. The related research and development of this technology is part of UDC’s long-term energy efficiency roadmap, which aims to continue to expand the company’s coverage of OLED solutions and continue to enhance the company’s value to customers, industries and consumers. As companies continue to improve the energy efficiency of their products, devices ranging from smartwatches to TVs will have better performance, longer battery life and brighter displays.

Another important development is related to the wider use of flexible panels for OLEDs. The introduction of flexible panels means that display devices will no longer be limited to flat, fragile glass substrates, but can be manufactured on highly flexible, bendable and foldable plastic and other substrates. This opens up a host of new opportunities for display devices that need to be integrated seamlessly into everyday devices – allowing them to be folded, rolled and bent without affecting the visual quality or performance of the device. In fact, some market analysts estimate that the foldable smartphone market will quadruple to approximately 55 million units by 2025. Companies such as Samsung, Oppo, Vivo, Xiaomi and Google have also launched folding screen mobile phone products.

Finally, as more and more car manufacturers begin to design and develop new generation car dashboards and new electric vehicles, the automotive industry has become a key market for OLED technology. Interior displays, taillights, and even rearview mirrors can be enhanced using OLED technology to achieve wider viewing angles, better performance in extreme temperatures, and lower energy consumption.