Department of Rearch & Development | 26 SEP 2023 | Werner

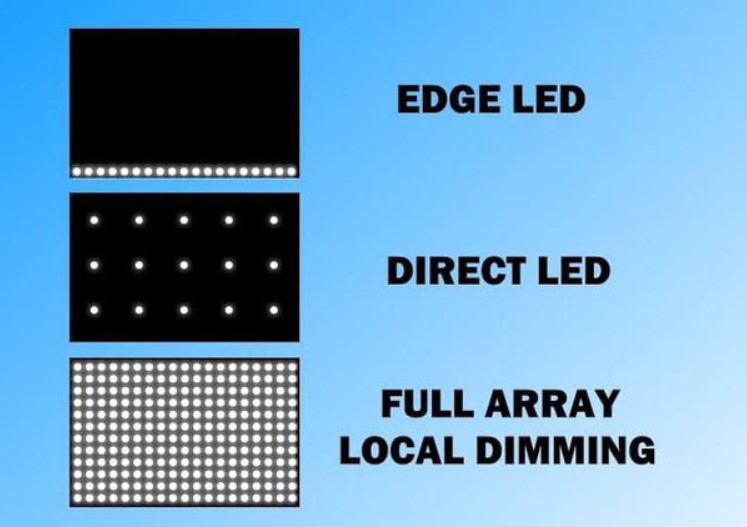

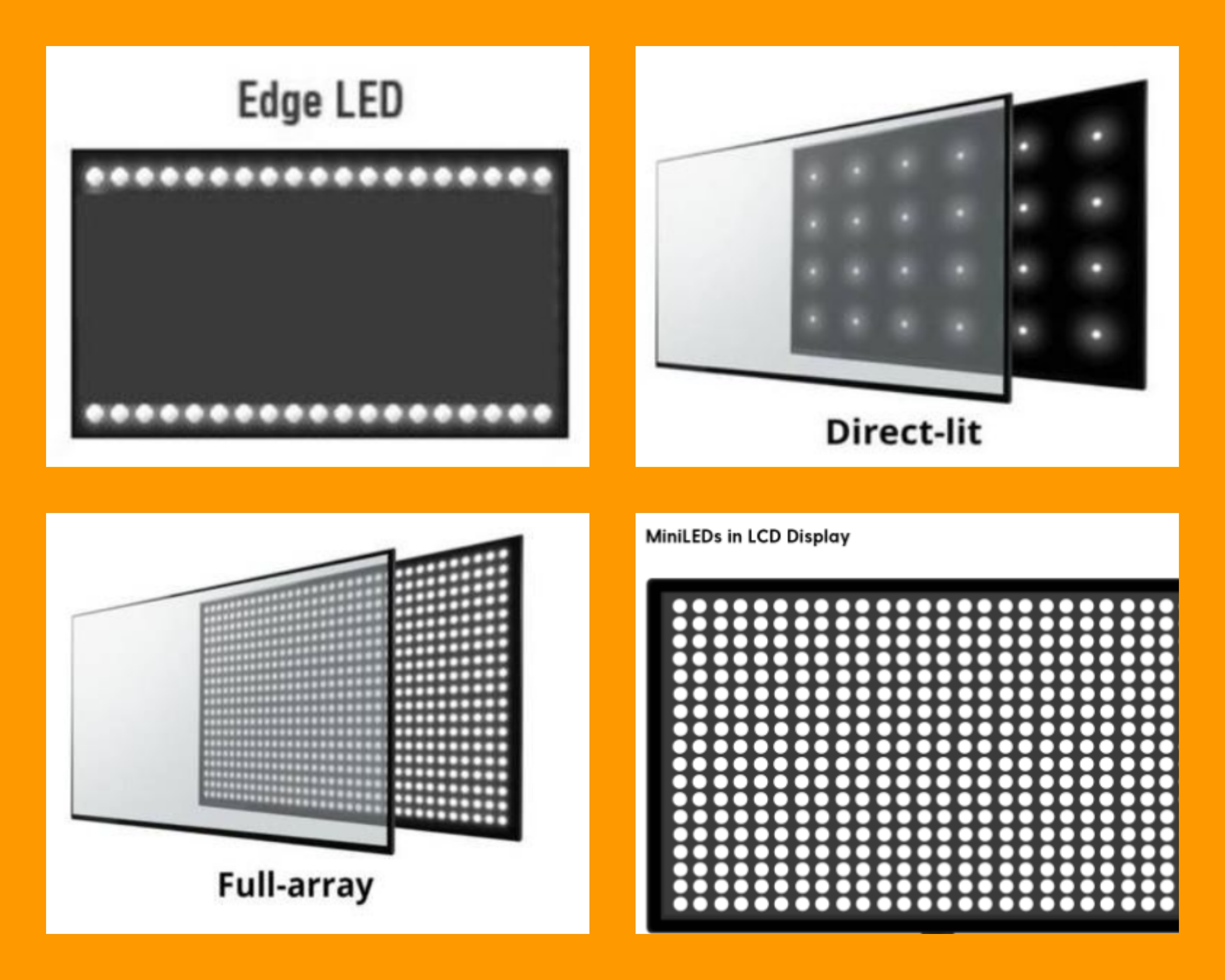

If you have read the article hyperlink: The Evolution of LCD TV Backlight Technologies, you would understand the rudiments of LCD TVs. Generally, a LCD Module is composed of LCD open-cell (OC) and backlight module (BLM). For LCD OC is non-luminous device, thus, LCD OC needs BLM to provide a planar surface light source. The performance of the BLM directly determines the display quality of the LCD OC. According to the location of light source, BLM can be classified into edge-lit type and direct-lit type.

Edge-lit Backlighting

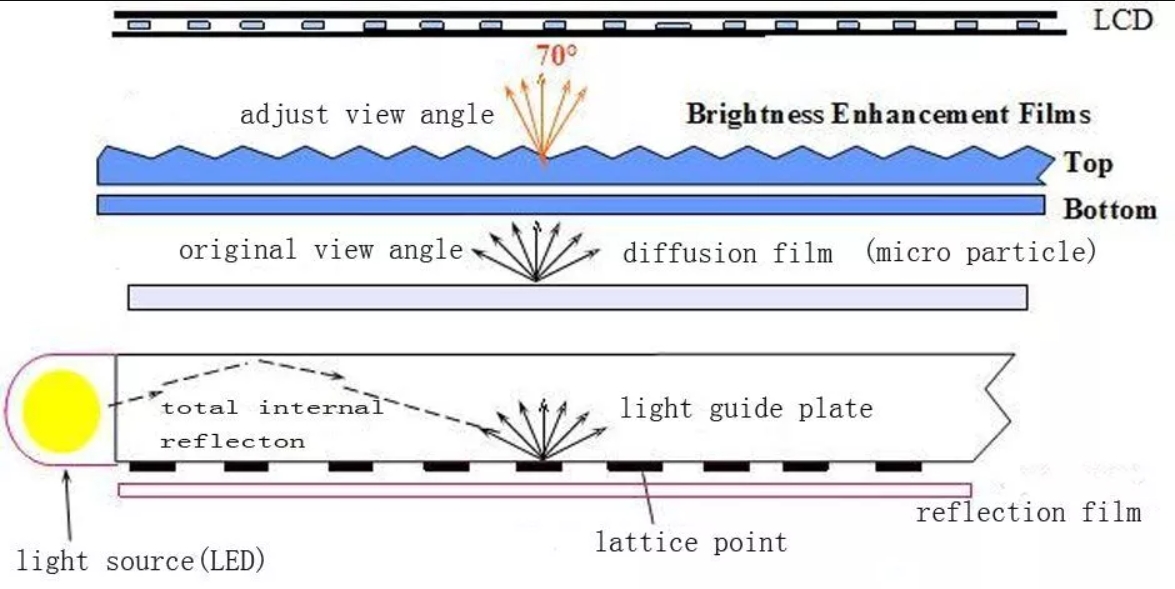

Typical edge-lit BLM consists of light guide plate (LGP), diffusion film (DF), brightness enhancement film (BEF, as known as prism sheet), reflection film (RF) and light source.

Inside the edge-lit LCD Module, the LED strips are arranged along the top and bottom edges of BLM chassis. As the light come from the perimeter of the Module frame, edge-lit LCD requires LGP to convert point or linear light into uniform planar light source.

During the switch from CCFL to LED backlighting, edge-lit arrangements were created as the first step. At first, the transition was such an improvement that most manufacturers of TV/monitor were happy with it for three reasons:

- The layout and arrangement of LED strips in edge-lit BLM is almost exactly the same with that of CCFL. This striking similarity allowed manufacturers to clear their old stocks of components which were previously designed for CCFL. Therefore, they could accomplish the seamless and smooth transition from CCFL to LED backlighting at minimum cost.

- Edge-lit BLM in TVs allow for a thinner and slimmer profile than TVs with other BLM solutions.

- When TV makers tried to boost the transition from CCFL to LED backlight, they started with small and medium size TVs such as 22”, 24” and 32”. They found that edge-lit BLM can achieve a decent effect using the least number of LEDs in small and medium size TVs.

Although edge-lit BLM could obtain basic brightness with the help of LGP, a large amount of light is not effectively utilized during transmission in LGP, resulting in a low light utilization and luminance uniformity.

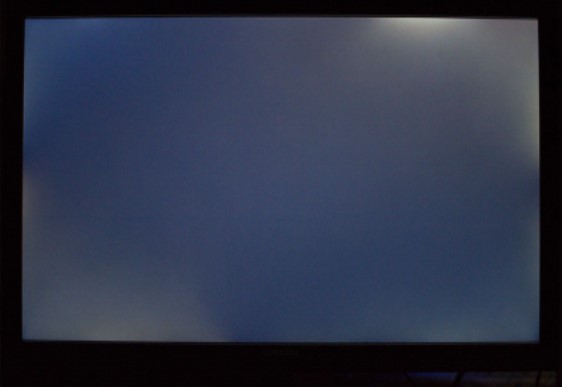

TVs using edge-lit BLM means the light source comes from a strip of LEDs which are placed on the rim of the screen, either at the bottom or on either side of the panel. This structure struggles with uneven illumination: the closer to the perimeter, the brighter the area; the closer to the center, the darker the area. It causes the “blooming effect”: dark parts aren’t as dark as they should be and look more grey or blueish; bright parts aren’t as bright as they could be.

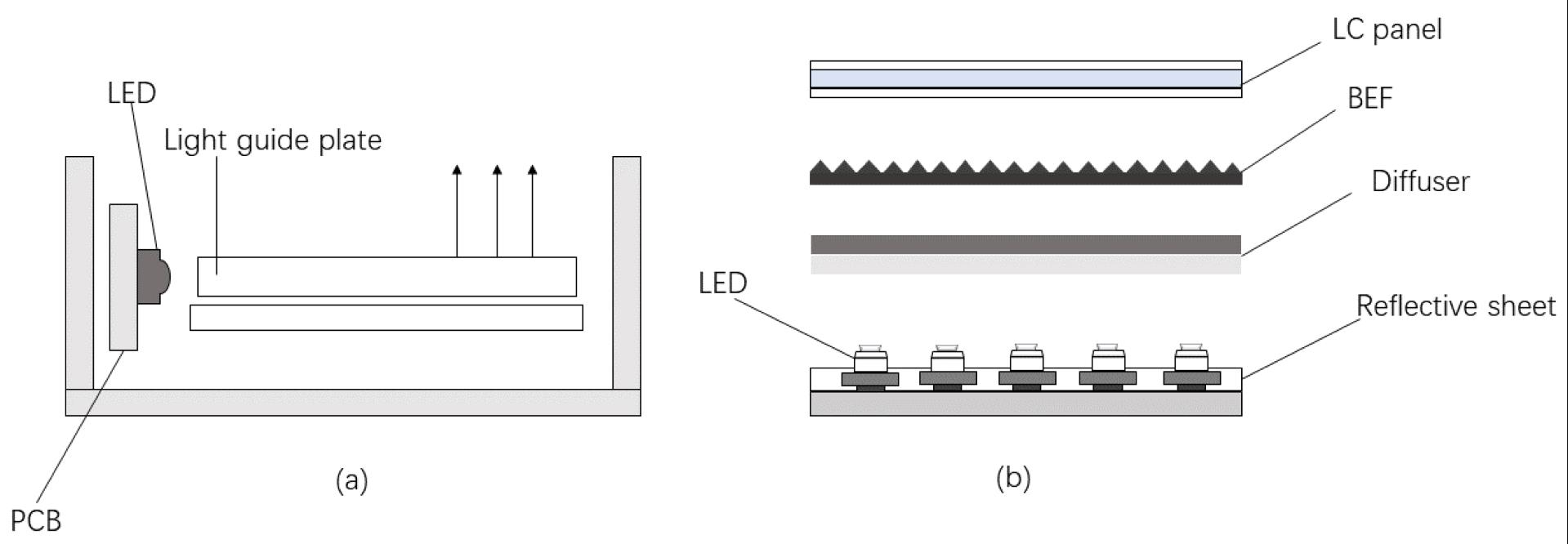

To get a fairly uniform amount of light across the LCD panel, especially in big and super-big size TVs, direct-lit BLM is introduced to overcome the drawback of edge-lit.

Direct-lit backlighting

Typical direct-lit BLM consists of Reflective sheet, Diffuser, brightness enhancement film (BEF), secondary lenses and light source.

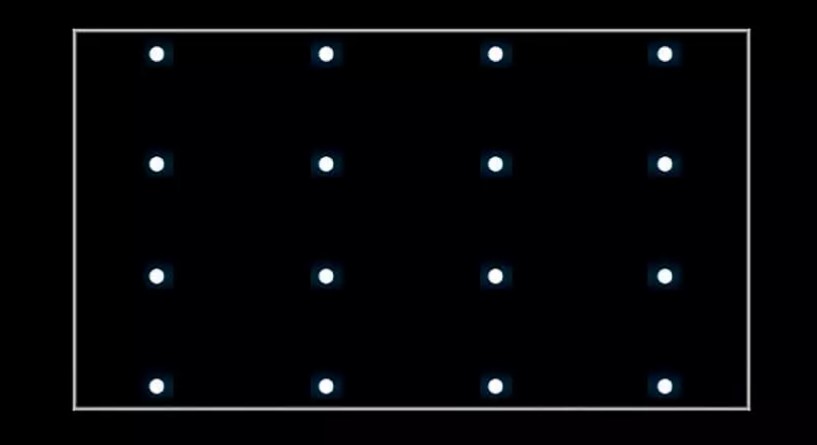

Inside direct-lit LCD Module, LED chips are set in rows across the back of LCD panel, namely, tightened by screws or adhesive on bottom chassis of BLM. Lights are adjusted by secondary lenses. They reach the LCD panel in perpendicular angel after passing through diffuser and BEF.

Secondary lenses are employed to redistribute the light from LED sources to reduce the package density. The use of secondary lenses allows us to generate an optimum IDU at a prescribed package density and lighting distance, which offers high degree of freedom for designing LED backlight.

This inherent advantage in light path makes direct-lit BLM to obtain much higher light utilization and luminance uniformity than edge-lit one.

However, direct-lit BLM has its limitations too. Because the entire LCD panel is lit uniformly, there’s little to no dynamic range offered by the display.

One common problem caused by this uniform backlight approach is that darker portions of the display are still illuminated, resulting in black portions of the screen appearing grey, a phenomenon called “elevated black levels”. It’s especially noticeable on letterboxed movies, which will have a distinct unwanted glow in the black bars above and below the picture.

Full-array with local dimming (FALD)

After entering the HDR era, direct-lit backlight has also been improved and upgraded, that is, full array with local dimming (FALD). In order to improve the contrast ratio and eliminate the elevated black levels that plague direct-lit TVs, FALD backlight are divided into multiple zones, so that it can obtain more accurate and dynamic control on LED modules. When it comes to a scene with light and dark elements, e.g., the moon night, all LED modules in a specific area will be switch on or off.

The more local dimming zones a TV has, the deeper blacks and brighter highlights it can delivers. Currently, the highest number of backlight partitions (dimming zones) on a high-end TV using FALD is 2,000, while the number of backlight partitions for an entry-level TV is around 1,000. Of course, there are also 500 or even fewer partition backlights.

Mini-LED backlighting

Mini LED, as we can learn the principle of implementation from its name “Mini”, which implies that it can improve the brightness of the LCD panel through reducing the size of LED chip so that the same panel can accommodate more LED chips while maintaining the same area. In the beginning, the standard size of Mini LED chips ranged from 200 microns to 100 microns. With the efforts of the whole industry, manufacturers leap forward to the latest range from 50 microns to 100 microns, boosting the brightness improvement from a few hundred nits to thousands of nits.

Mini LED backlight were firstly applied in the TV industry. Due to its high brightness, high contrast and other features that improve picture quality, TVs equipped with Mini LED backlight have achieved excellent market performance as soon as they were launched.

The increasing number of LED chips has also given rise to Local Dimming technology, which refers to dividing the entire backlight into more independently controlled zones. Mini LED TV achieves higher contrast ratio through algorithm which controls the dimming in a single zone. Moreover, since most Mini LED backlight unit adopt a direct-lit structure, Local Dimming technology can also effectively improve the light leakage problem that has always plagued the LCD TVs.

Dimming techniques for LCD backlight

LCD TVs/monitors have been widely used in different environments and conditions which require the brightness (luminance) of an LCD TV/monitor can be altered to match both bright and dim environments. This allows a user to set the screen to a comfortable level of brightness depending on their working conditions and ambient lighting. Manufactures of LCD TV/monitor generally apply two dimming techniques for brightness control in their products.

- DC (Direct Current) Dimming

DC dimming has been used in LCD TV backlight brightness control for years, it simply controls the brightness by changing the input power of the LED light. There is an equation in electricity that power is the product of voltage and current (Power = Voltage x Current), so varying any of this variable, we can control the power supply to the backlight and adjust the brightness.

When high brightness is required, the voltage is raised, and when low brightness is required, the voltage is lowered. Although it sounds simple on the words, it is not that simple after all.

However, the problem with DC dimming is that both the cost and the circuit complexity are high, so manufacturers have come up with another technique, which is PWM dimming.

- PWM (Pulse Width Modulation) Dimming

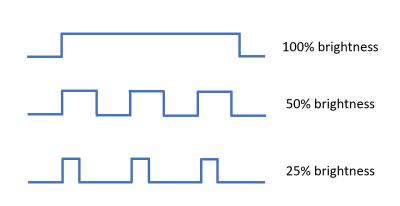

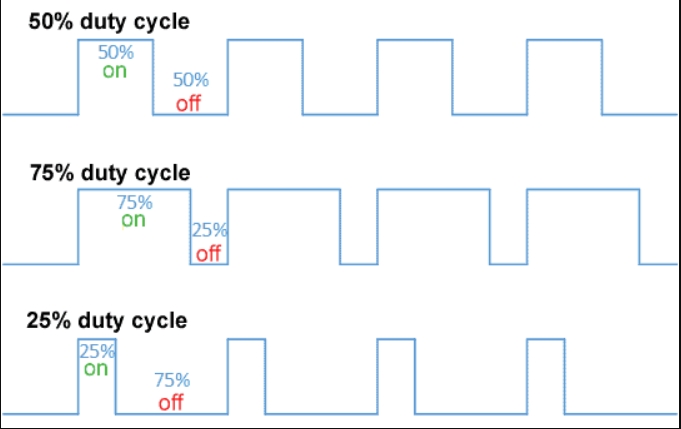

PWM (Pulse Width Modulation) is the most prevalent technique for dimming the backlight by far. It creates modulated electronic pulses or the electronic pulses of the desired width.

The LEDs are fed with pulsed high current for a short period of time, instead of a constant DC current. For example, a normal LED driving current is 120mA. Now we apply 5 times the current, 600mA; but only apply for 1/5 of the time. The LCD TV doesn’t consume more electricity. Yet its perceived brightness is a lot brighter.

Generally, the pulse frequency repetition is higher than 100Hz but lower than 1000Hz, which cycles the backlight on and off so fast, that human eye can’t detect flickering.

This technique can also be applied to provide a normal looking brightness level to LCD TV and save at least 50% energy consumption at the same time. It is very important for battery operated product.

However, this technique has some side-effects which cause eyestrain, eye fatigue, headaches and other associated issues for people sensitive to it. Some manufacturers are now adopting new methods to address these concerns and provide flicker-free backlights instead. As awareness grows, more and more manufacturers are focusing on eye health with their monitor ranges.

Summary

Nowadays, WLED + Edge-lit backlighting + PWM dimming is the most prevalent and cost-effective configuration for LCD monitors. The combination of WLED + Direct-lit backlighting + DC dimming dominates the LCD TV market. Of course, high-end monitors and TVs are not included in this list. There are also many full-array backlight monitors/TVs. As for backlights such as RB-g LED, although they are rare, they existed at least a few years ago.

The backlight is a very important part that greatly affects the function of TVs and monitors besides the LCD panel. If the backlight is not well designed and developed or is cut corners by the manufacturer, various problems may occur, such as unbalanced brightness screens, extremely low brightness, serious light leakage, etc. The backlight parameters are often omitted by most consumers. Therefore, if you see a monitor with good parameters on paper but an extremely low price, you should be careful.